Range of mobile crushing, screening, shredding and conveying equipment

Bison 35

Bison 120

Bison 160

Colt 600

Colt 800

Colt 1000

Harrier 220

Harrier 750

Falcon 820

Falcon 1220

Falcon 1230

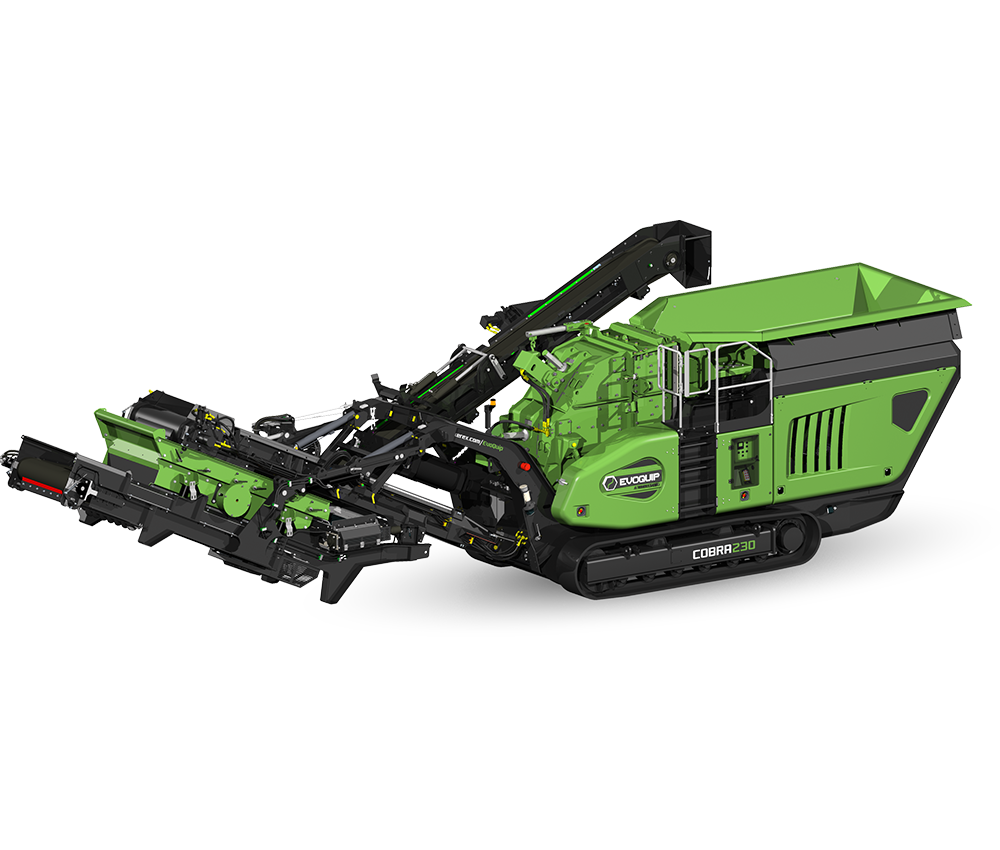

Cobra 230

Uncompromised quality

The range of innovative machines available provide efficient production, low operational costs and ease of maintenance, so end users are sure to find the correct machine for their application.

Committed to getting the right solution

Our team of industry experts have years of experience and a knowledge of the vast range of machinery options. This means that we are able to work with you to understand your goals and advise the best solution that fits your budget, whilst achieving your goals.