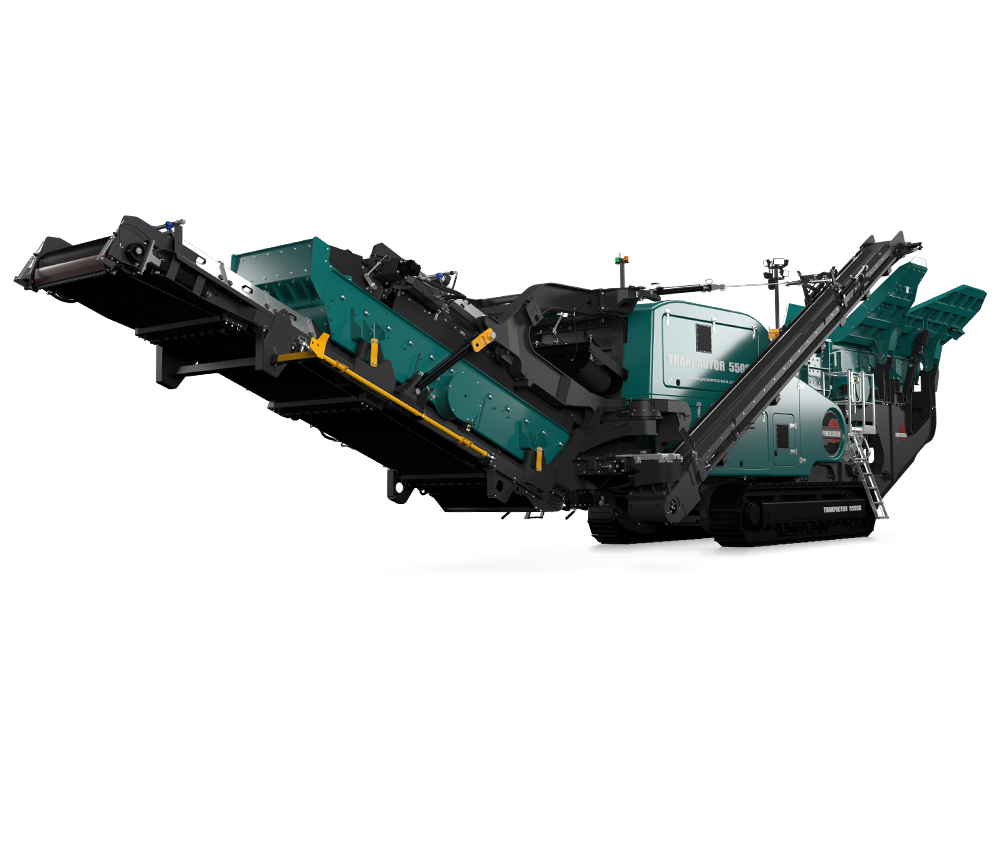

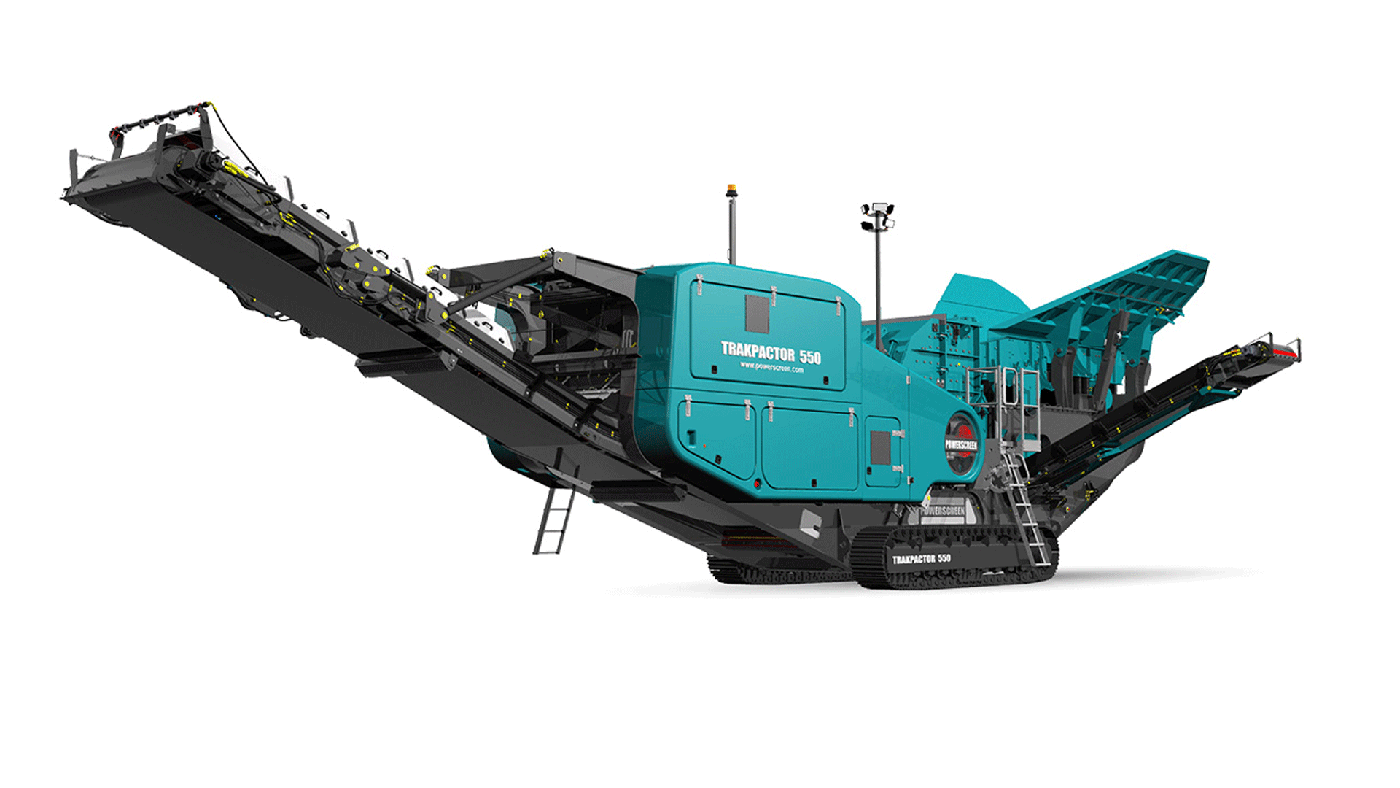

Why Choose this product?

The Powerscreen® Trakpactor 550 horizontal shaft impactor is designed for processing soft to medium-hard primary & secondary materials such as natural rock & construction derived materials like asphalt, recycling & demolition waste. Material is fed into the large feed hopper, common on both vibrating grizzly feeder & live pre-screen versions, both feature a selectable crusher bypass facility & optional fines discharge conveyor.

Specification

Output Potential 500tph (550 US tph)*

Transport Dimensions Width: 3m Length: 17.46m Height: 3.8m

Working Dimensions Width: 6.96m with bypass conveyor Length: 17.82m Height: 5.15m

Weight Tier 4F Pre-screen: 126,656lbs